Additive manufacturing systems are devices and equipment that produce three-dimensional objects by combining different materials layer by layer. These systems are used in different industries, especially in areas such as product prototyping, parts manufacturing and custom manufacturing.

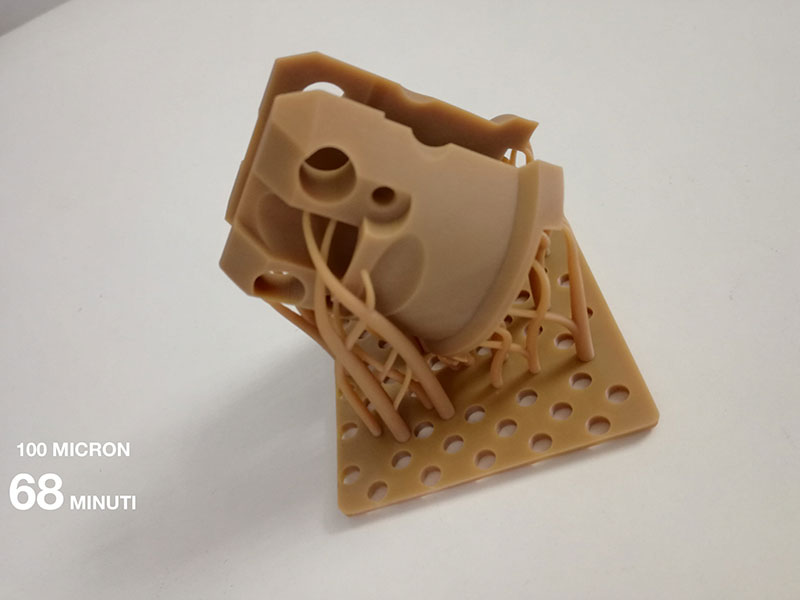

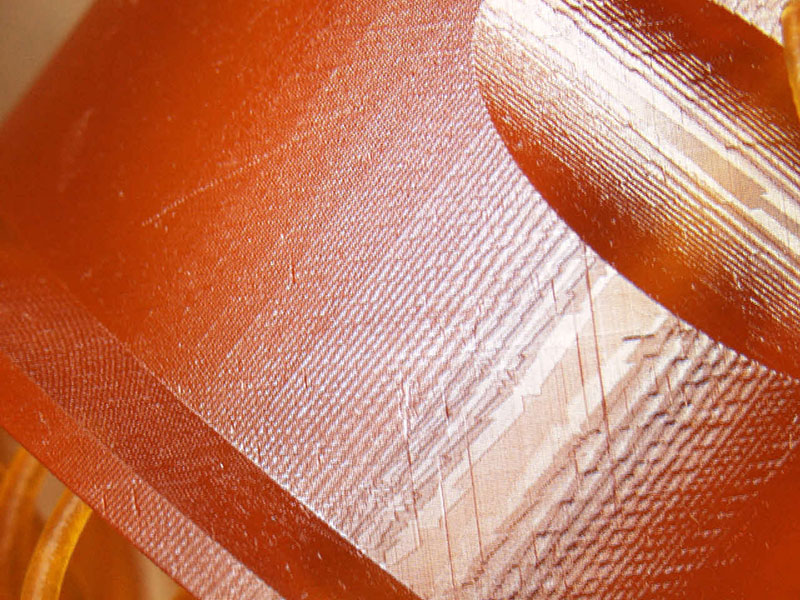

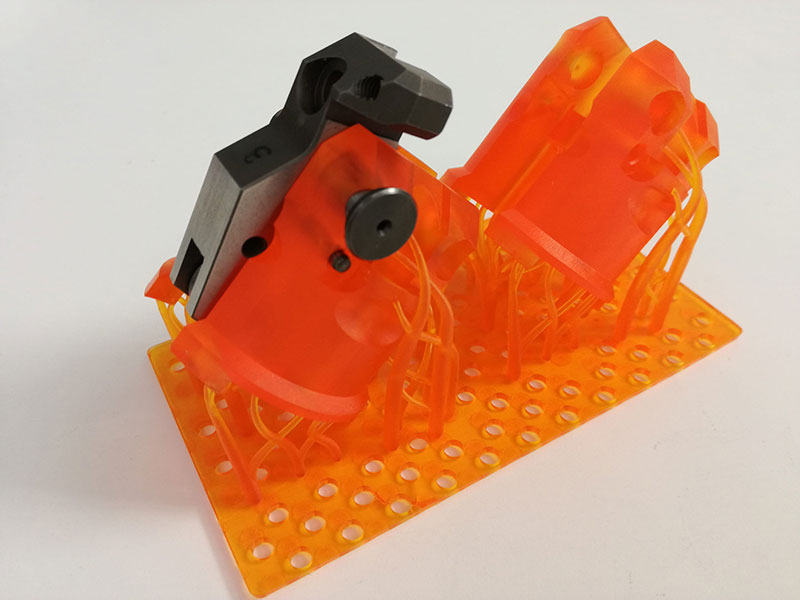

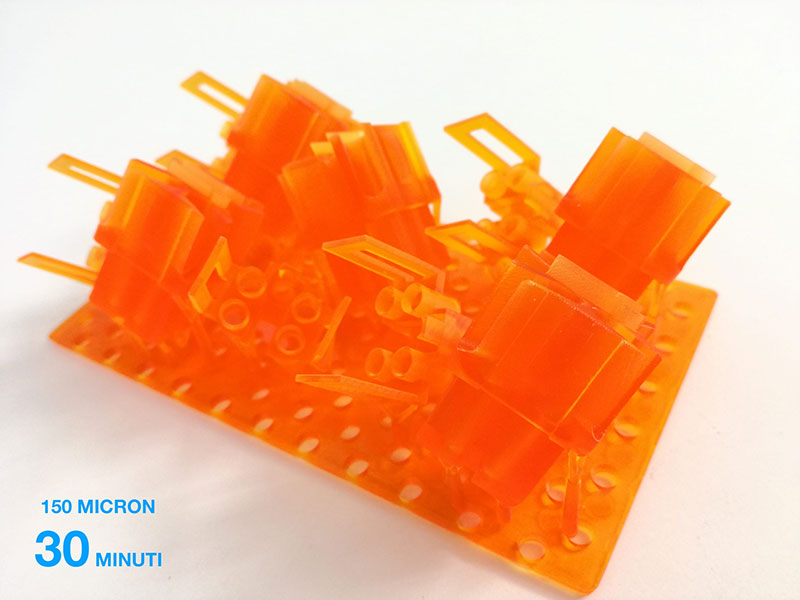

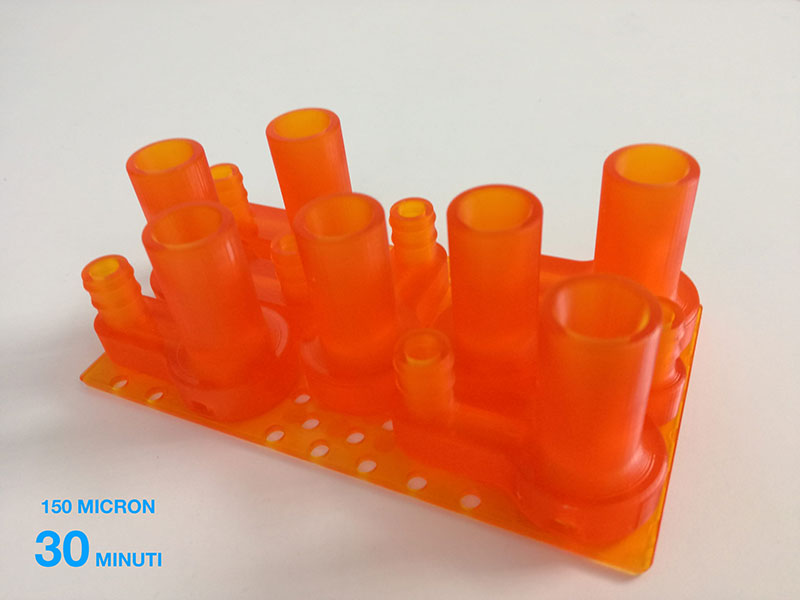

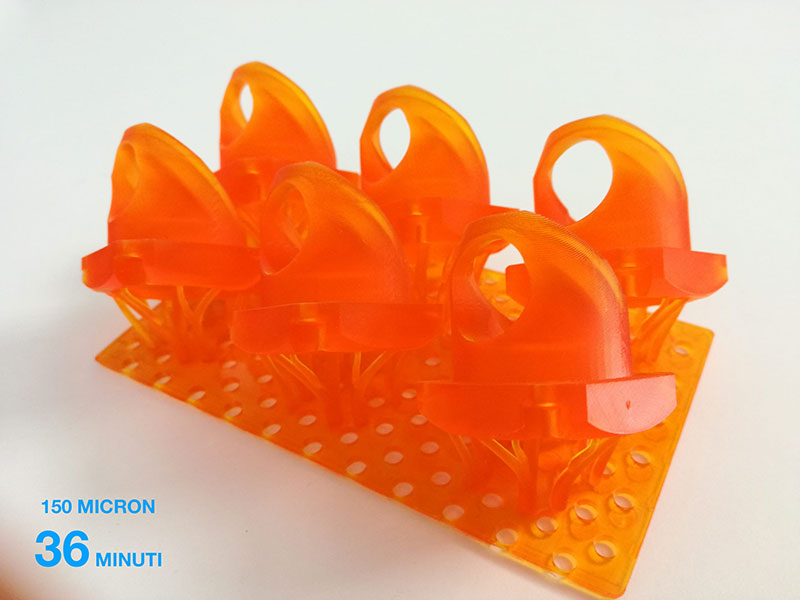

Additive manufacturing systems work using several different technologies. These technologies include methods such as assembling plastic filaments, melting and sintering metal parts with a laser, assembling melted metal parts with an electron beam, and chemically joining various materials.

Additive manufacturing systems include many models with different features. These models include desktop, mid-sized, and industrial-sized models. There are also models with different features, such as high-precision models, high-speed models and large-volume models.

Additive manufacturing systems provide many advantages. These benefits include faster prototyping, faster part production, greater design freedom, less material usage and less waste generation. In addition, additive manufacturing systems provide time and cost savings by using them in the production of complex and heavy workpieces.

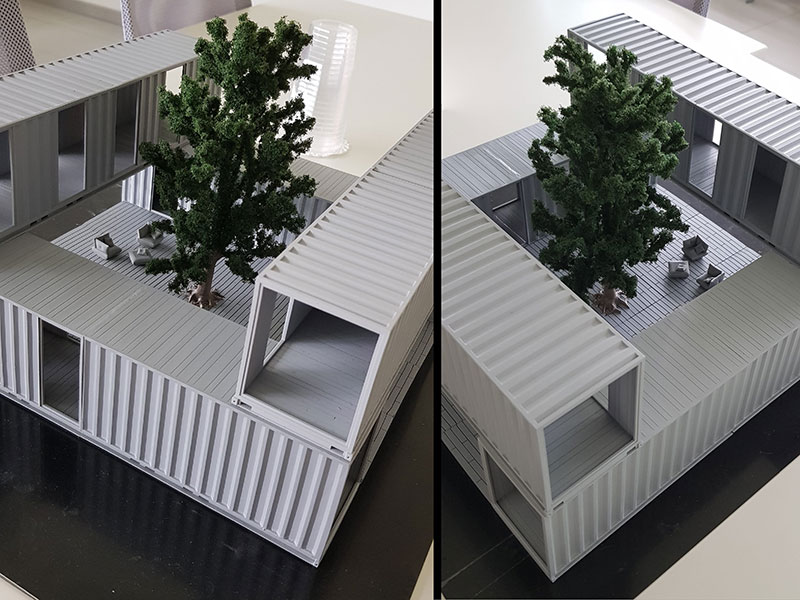

Additive manufacturing systems are used in many industries. These include industries such as automotive, aerospace, medicine, dentistry, mechanical engineering, biomedical, architecture, defense and arts.

Ürünlerimiz hakkında bilgi almak ya da teklif talepleriniz için formu doldurun.

Satış Mühendislerimiz sizi arasın.